Jonas Asprion was intrigued by combustion engines and driving dynamics, leading him to always use and ride a motorcycle. This passion eventually brought him to ETH Zurich, where he delved into mechanical engineering with a specific focus on control systems. “From BSc to PhD, I was at ETH Zurich, studying mechanical engineering and specializing in control systems,” Jonas recalled with a smile. “I then spent about five years working on the control of industrial combustion engines with the company that had been the industrial partner during my PhD.”

Have you ever wondered what makes those powerful combustion engines in cars and machines tick? Jonas explains, “Today’s combustion engines are very complex systems. The control unit has been refined over decades, and one always works on a tiny part of it to achieve marginal improvements.” After five years of this meticulous work, Jonas was ready for a change. An opportunity came knocking when he learned that a former colleague from ETH Zurich was looking for someone to build up R&D at Tool-Temp AG, focusing on control systems. So, in May 2018, Jonas took the leap and joined Tool-Temp AG.

What does it take to transition from working in a large corporation to a smaller, innovative company? For Jonas, it was all about mindset. He says, “As a control-systems engineer, I learned to abstract and always see the entire system and its internal workings. This view, or rather mindset, on both the technological and economic levels, allows me to make well-thought-out decisions that consider all cross-couplings and dependencies.”

Jonas’s academic journey, culminating in a PhD, taught him to think and act autonomously, setting and persistently pursuing relevant goals. His tenure with the global corporation underscored a crucial lesson: “Leadership affects the power of a team, a department, and an entire company.” Armed with this insight, Jonas was eager to foster an environment ripe for innovation and development at Tool-Temp AG that was starting on a green field.

Leading Innovation

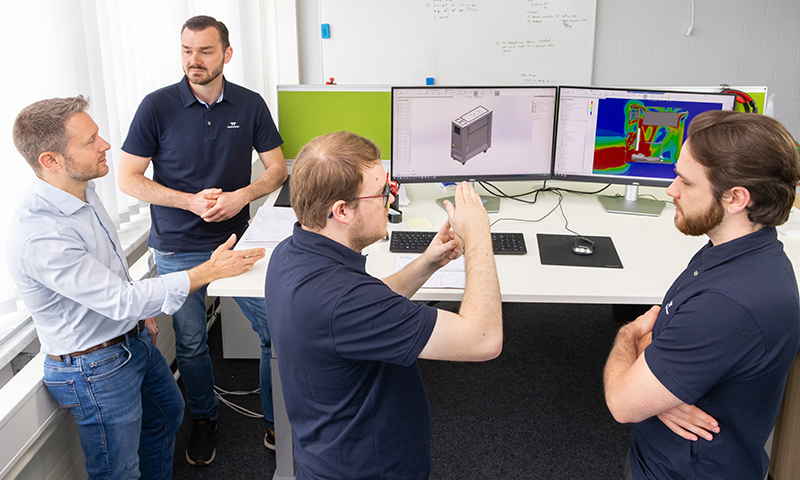

At Tool-Temp AG, Jonas leads the entire R&D department, balancing technical prowess with personal leadership. He bridges the gap between technological opportunities and the company’s strategic vision. “I represent technical aspects and introduce technological opportunities to the C-level, thus contributing my part to shape the vision and strategy of the company,” Jonas explains.

But his role isn’t confined to the headquarters in Sulgen. Jonas ensures that R&D is seamlessly integrated into Tool-Temp’s global network of affiliates and resellers. “I have to see and implement R&D as a part of the whole and avoid building an island,” he says.

People are at the heart of Tool-Temp AG’s progress. Especially in R&D, with the current skills shortage and rapidly changing market demands, it’s vital to develop and retain talented individuals. Jonas emphasizes, “It is of utmost importance to keep and develop existing human resources and build a well-rounded, complementary, and flexible team.”

Jonas also understands that the project portfolio must align with the company’s strategy and core competencies. Tool-Temp AG, as a manufacturing company, relies on a tight integration of R&D with every other department—operations, production, quality management, sales/marketing, and HR. “It is key to constantly refine those interfaces to allow flawless operation throughout the company,” he notes.

To ensure efficient and productive work, Jonas is responsible for the tooling in R&D. He insists on a set of powerful software tools that truly enhance efficiency without adding unnecessary complexity. “Only tools that actually work and impose minimal overhead are accepted by a team,” he explains. This also means ensuring integration with software used by other departments to avoid creating data silos.

Shaping Tool-Temp AG’s technological vision requires Jonas to stay vigilant about new trends and opportunities. However, he remains grounded, critically assessing the real-world potential of new ideas. He keeps the company’s financial and staffing situations, project portfolio, skill sets, and sales network capabilities in mind when making strategic decisions. “The most important part is to keep both feet on the ground,” Jonas asserts.

Crafting the Future

Building and maintaining a strong core team in R&D is a constant challenge, and Jonas knows this well. He focuses on the individuals behind the roles, understanding their needs and potential. “No company, no team, and no employee is the same, so flexibility and constant introspection are key,” Jonas says. Taking the time to address these aspects, despite the busy nature of business, is a worthwhile investment.

Tool-Temp AG has many long-established structures that take time to change. Jonas sees it as his role to help break these down and transform Tool-Temp into a modern company. Communication is crucial in this process. “Getting everyone on board and involved is always about the people,” he notes. The company is fortunate to have many senior employees, some with up to 35 years of experience, and Jonas emphasizes the importance of including them in this journey.

The wisdom of these senior employees brings Jonas to another vital aspect: Knowledge Management. It’s essential to gather the existing knowledge from long-term employees, combine it with new insights, and make it accessible across all departments, even the non-technical ones. “I aim to directly apply the most recent technological developments, such as large language models (LLMs) like ChatGPT,” Jonas explains. Traditional static content, like Wikis or white papers, is becoming obsolete.

Managing the numerous challenges and keeping an eye on various aspects is one of Jonas’s biggest tasks. “There is no silver bullet. Just work hard, but effectively (doing the important things only) and efficiently (doing them quickly), with good but minimal tooling – the tools have to fit the work, not vice-versa,” he advises.

As a production-heavy small to medium-sized enterprise (SME), Tool-Temp AG doesn’t have dedicated resources for innovation but focuses on being innovative during regular product development. To foster research and innovation not strictly related to product development, Jonas seeks collaboration with academia and participation in larger European research projects. “The basic idea is to keep up with all technological developments that could be relevant for our business. Then, distil those that have real potential, and align them with the strategy and the current and future product portfolio,” he says. Balancing between falling behind and overstraining the limited resources is crucial for sound and efficient product development in R&D.

The Development of IRIS

At Tool-Temp AG, the most significant innovation to date is undoubtedly IRIS, the new control system for their temperature-control units. Unlike the old controller, which was just a standalone component, IRIS fully integrates with the units of the new MATIC lineup. It enables constant self-diagnosis and optimal interaction across the entire system. Jonas explains, “IRIS brings user experience and interaction to the next level, providing simple-to-operate and self-explorable functionality, context-aware instructions, and one-touch automated procedures.”

IRIS is a game-changer in many ways. It sets a new standard in energy efficiency with its optimal interaction and variable-speed pump drive. Ergonomics have also been considered, resulting in the world’s first foldable HMI on a temperature-control unit. The system’s modularity ensures that IRIS can be extended even in the field, meeting the rapidly changing demands for industrial connectivity.

Beyond the immediate benefits of IRIS, its role as an enabler for future developments is crucial. “We see IRIS as the brain and the nervous system, enabling us to harness the full combined potential of upcoming cutting-edge technology,” Jonas says.

Rolling out IRIS across the entire range of temperature-control units, and completing the MATIC lineup, is something Jonas eagerly anticipates. He is also looking forward to refining IRIS and maximizing its potential to significantly enhance customer benefits. “Unfolding the full potential of IRIS and honing its rough edges will be a satisfying task,” Jonas notes.

Alongside this evolutionary process, Tool-Temp AG is about to embark on developing components for an entirely new, revolutionary line of units. This venture into uncharted territory is thrilling for Jonas and his team.

Innovation in a Slow-Moving Industry

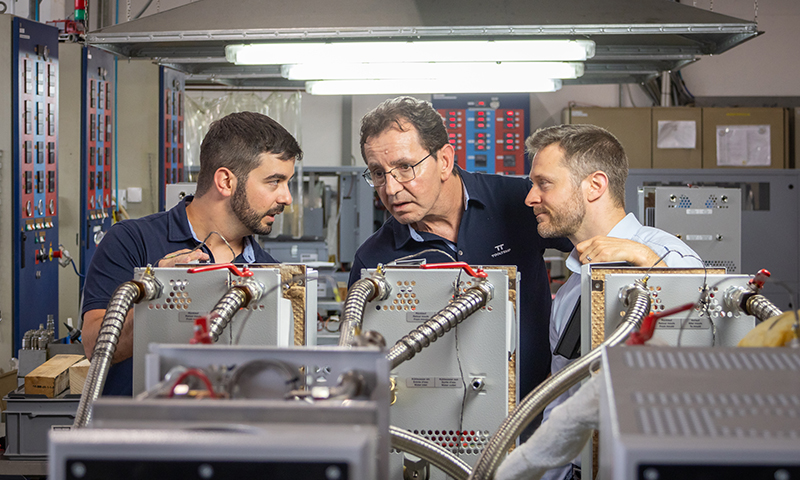

The world of temperature-control units and water chillers moves at a deliberate pace. The main technologies are well-established, focusing on cost and energy efficiency. Jonas shares, “Added customer benefit mainly comes from usability, reliability, and innovative solutions in the details.” Tool-Temp AG emphasizes outstanding user experience, quality, and custom solutions for key components. When they can’t find a third-party component that meets their standards for performance, quality, and price, they develop and produce it themselves. This “do-it-yourself” mentality involves initial costs but offers long-term advantages, builds know-how, and makes the company flexible and quick to adapt to changing demands.

Larger trends are also shaping the industry. Industrial connectivity, from the shop floor to the cloud, is advancing rapidly. Continuous monitoring of condition and energy consumption and predictive maintenance are replacing regular inspections and retrospective assessments. Trends in manufacturing, such as rapid mechanical prototyping and cost-efficient production of small batches through additive manufacturing, also significantly impact the business.

Tool-Temp AG stays at the forefront by being a member of major industrial-communication organizations like PNO, ODVA, and OPC Foundation. Regular visits to trade fairs across various fields help maintain connections with current and potential suppliers of innovative services, materials, and components. “Consistent study of digital and print media also helps us,” Jonas adds.

Furthermore, Tool-Temp AG always aims to have at least one innovation project in collaboration with a university or within a European Union research cluster. Collaborating with universities on student theses or providing internships keeps a direct line to academic cutting-edge research. “We keep an open mindset, we try out new things, take a small step, then evaluate. If we find something to be directly beneficial or at least promising, we move forward,” Jonas explains.

Navigating Shifts in the Market

The landscape of temperature control is shifting, with low-tech applications moving almost entirely to Asia and medium-tech following suit. Jonas’ strategy at Tool-Temp AG focuses on investing in high-tech products to maintain sales in Western countries. “We will invest in the most demanded high-tech products to keep sales up in Western countries while not neglecting the cost-effective, feature-reduced but same-quality base units to keep pushing into Asian (and other) markets,” he says.

Energy efficiency is a significant trend in the industry. Moving heat between different temperature levels always involves some loss. The goal is to avoid unnecessary heat movement by precisely controlling all heat flows. “Whether heating or cooling, we aim to use only as much pumping power as needed to transport that heat,” Jonas explains. Excess power should not be spent only to be counteracted later. Tool-Temp AG is investing in developing sensor, pump, and valve technology to enable this precise temperature control.

Another trend Jonas has noticed is the shift from smaller, simpler units as series products to larger, more complex units that are often customized or even fully custom-engineered. Custom engineering demands different processes, skills, and sales channels than selling off-the-shelf products. With R&D closely collaborating with production, Tool-Temp AG benefits from mutual inspiration and enhanced flexibility. “We keep building up internal know-how to be able to quickly react to such changes,” Jonas emphasizes.

Leading by Example

Jonas believes in building strong personal connections with everyone he works with. He meets everyone at eye level, regardless of their position or tenure. “My goal is to have a close, open, and transparent relationship with each and every employee,” he shares, a goal he achieves through frequent one-on-one meetings. Jonas leads by example, focusing on developing his team members so they can operate autonomously. He doesn’t adhere to a single leadership style but constantly refines his approach to best suit the company and his team.

Jonas strives to be an inspiration to his team. “How should anyone be motivated, creative, and explorative if their leader sets an example that is the exact opposite?” he asks. Despite setbacks, criticism, misunderstandings, and bad days, he emphasizes the importance of resilience and maintaining a focus on the positive aspects of their work.

Creativity, Jonas believes, requires space, motivation, and inspiration. Space comes from the ability to act autonomously, which he fosters by transferring responsibility and developing affinity. Allowing team members to freely choose their path toward a goal and offering flexibility in working time and location, such as home office options, also helps.

Motivation is highly individual, so Jonas makes it a priority to understand what drives each employee. Providing purpose, setting challenging goals, and appreciating the effort and hard work everyone puts in creates a common foundation. “A balanced and well-attuned team – on both the personal and skills level – spurs both motivation and inspiration,” he notes.

Fostering a Family Culture

Being family-owned, Tool-Temp AG feels like a big family to its employees. Personal interaction takes precedence over excessive bureaucracy and paperwork. As an SME with development and production on a single site, the company enjoys flexibility and quick decision-making. “These advantages largely depend on the mindset and personal commitment of the employees,” Jonas Asprion notes. Mutual commitment and taking responsibility—loyalty, in short—create an enjoyable and productivity-enhancing culture at Tool-Temp AG.

The company’s vision and goals are always defined with the employees in mind. Jonas constantly asks, “Will we lose them in the process? How quickly can they adapt to this or that disruptive change we are envisioning?” Maintaining the company culture takes priority over overly ambitious goals and far-fetched visions. If employees cannot understand and identify with a vision, achieving it is impossible. “A bright vision and challenging goals do motivate, but only if they align with the deep-rooted values of the employees and seem achievable,” Jonas explains.

There’s no one-size-fits-all solution, no single go-to schoolbook for anything—whether it’s working styles, motivation, project management, or development itself. Having a background in different approaches helps, but it’s crucial to always consider the specific combination of task, environment, and people. “It is the people that make a company,” Jonas emphasizes. “So, in short: Be open-minded, flexible, see (and treat) each employee as an individual, meet them at eye level with appreciation, and push innovation only at a pace at which all employees can follow.”

Advancing Development at Tool-Temp AG

Jonas spearheaded significant technical advancements at Tool-Temp AG, marked notably by the adoption of model-based development methodologies. On one hand, this involved implementing model-based development for control logic and algorithms. “The aim is to frontload work to understanding physics, apply a suitable degree of abstraction, and come up with a mathematical model that allows simulation of hundreds of scenarios within seconds, on a standard laptop,” Jonas explains. This approach, known as “Software-in-the-Loop,” encompasses approximately 75% of development and control-algorithm tuning in a virtual environment, further optimized through mathematical optimization.

On the other hand, Tool-Temp AG made substantial strides in mechanical development, transitioning from traditional trial-and-error methods to systematic development with virtual prototypes. Simultaneously, efforts towards integrating CAD data and ERP via a Product Data Management (PDM) system are paving the way for an integrated Product Lifecycle Management (PLM) and a comprehensive digital twin.

Personally, Jonas values his team as a cornerstone of success. “In six years, R&D evolved from a one-man-show into a robust, fully-fledged tech department that thrives on both technical and personal levels,” he reflects. The synergy between advanced methodologies and a cohesive team spirit was crucial in achieving milestones like the successful launch of IRIS in April.

Evolving Roles

Jonas is set to transition away from daily technical operations, project management, and direct leadership. With a cohesive and rapidly maturing team in place, he aims to delegate responsibilities to capable individuals whom he holds in high regard. His focus now shifts towards higher-level aspects such as technology strategy, aligning with sales and marketing perspectives, enhancing project portfolio management, and implementing company-wide integrated tooling. These initiatives form the foundation for sustainable efficiency improvements, fostering transparent information flow, aligning company-wide goals, and clarifying responsibilities.

Currently, Tool-Temp AG is actively enhancing its sales and marketing efforts to sustain continuous growth and innovation. Jonas envisions a future brimming with ideas ranging from incremental enhancements to groundbreaking developments, eagerly anticipating his role in steering these endeavors forward.

For More Info: https://tool-temp.ch/en