Ground Penetrating Radar Systems (GPRS) is the leading company in the United States able to Intelligently Visualize The Built World™ above and below ground to keep its customers’ projects on time, on budget, and most importantly, safe.

Founded in 2001, GPRS thrives thanks to its ever-present spirit of innovation. By visualizing possibilities for its team members, customers, and industry, GPRS innovates new opportunities for construction, facility and portfolio management, and safety.

From Humble Beginnings, a $160 Million Company Grows

GPRS’ beginnings were humble, as were President & CEO Matt Aston’s ambitions. His goal was to create enough income to support his young and growing family. So, he purchased a ground penetrating radar (GPR) unit from an ad in a magazine, reasoning that he could utilize it to help the construction industry see inside concrete slabs to locate post-tension cable, rebar, and encased MEP features to avoid dangerous and costly construction accidents. For most of its first year, the company was run from the Aston family car and dining room, with Aston making the rounds of the Greater Toledo, Cleveland, and Detroit areas in search of construction sites that could benefit from the technology.

Things changed when Aston made his now famous “One More Stop,” on December 23, 2001, at a construction site near the Detroit Metropolitan Airport. There, he encountered an executive involved in constructing the Detroit Westin Hotel.

“I was sure I was going to get kicked out of the trailer, but Gary Wolfe, the construction executive on the project for Walbridge Aldinger, read my brochure, looked over his glasses at me, and said, ‘Are you telling me this thing can find post tension cables in concrete?’ I said that it was the primary application for the technology. Gary then says, ‘This hotel has 400 rooms. The architect’s in Boston, the engineer’s in Atlanta, and our job is here in Detroit. I just got notified that I have to move every toilet flange, tub drain, every sink… All the drain lines for every bathroom in this hotel. We’ve already poured the slabs, the post tension cables are already in. Clearly, I can’t cut them. So, we’ve got to figure out what we’re going to do.’”

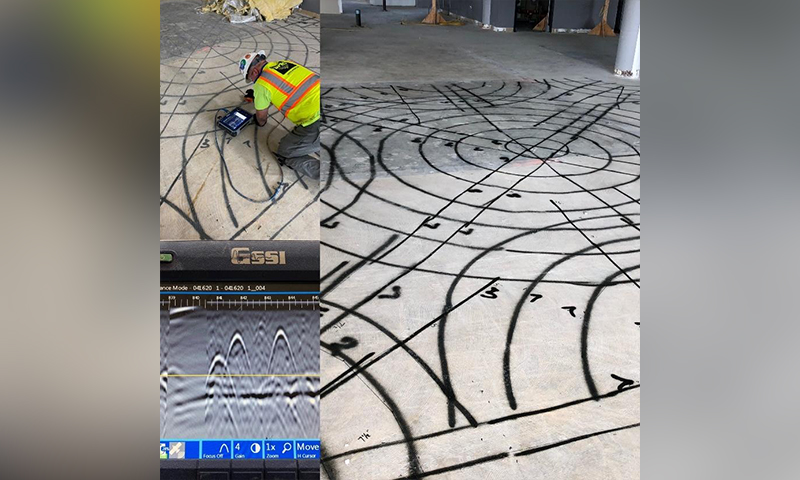

More than 2,000 concrete scans later, GPRS had located on every floor of the hotel, and established that GPR was an invaluable tool for construction safety. It also sowed the seeds of GPRS’ future – providing accurate as-built data with 99.8% accuracy.

You can hear Matt Aston recall that fateful evening and learn how “One More Stop” has become one of GPRS’ guiding principles, here.

Word began to spread about the new tool that was safer and easier to use than existing x-ray technology for imaging concrete, and soon, Aston had more business than he knew what to do with. Never one to shy away from a challenge, he began enlisting and training his friends to join GPRS and expand beyond the Midwest.

Chris Moore, GPRS Sr. Vice President of Internal Operations recalled how Aston’s father, Skip, tried to recruit Moore into GPRS. Moore was reluctant to join the new venture until a breakfast meeting nearly a year later. “Matt explained that he was looking for team members who would come on board. He said he’d give me business cards, equipment, and a truck, send me off to a market and to try to make a go of it. I thought that sounded really interesting, and that’s how I got my start.”

Moore went from expanding GPRS in northeast Ohio markets to relocating to Florida, where he created the first foothold for the company in the Sunshine State.

It was a risk to spread the fledgling firm’s assets so thin, but the strategy paid off and demonstrates what was to become one of many points of innovative thinking regarding how GPRS approaches growth: Leverage what you have to expand your footprint. That kind of leverage often requires outside-the-box thinking, like deciding to cover most major U.S. regions with what anyone would consider a skeleton crew of nine. However, Aston had complete trust in his well-trained and entrepreneurially minded GPR operators.

Their can-do attitude added successful job after job to the company’s resume. Below is a brief list of the “Milestone Jobs” that put GPRS on the map nationally:

- The Detroit Westin Hotel – 2002

- Trump Tower, Chicago – 2006

- BP Refinery, Chicago – 2007

- UCLA/UC Harbor Hospital – 2008

- The Austonian Hotel, Texas – 2009

- Elk City Wind Farm, Oklahoma – 2009

- Kohl’s/Davaco (Nationwide) – 2014

- Chevron, Texas – 2017

Now, the company has more than 500 elite Project Managers and another 300 corporate staff spanning the United States – each one as invested as the original crew in providing spectacular service with a consultative approach to customer needs. That continued top-down trust and personal accountability are key factors that allow GPRS to maintain a 99.8% accuracy rating in utility locating & concrete scanning on nearly half a million jobs and counting.

In Pursuit of 100% Subsurface Damage Prevention

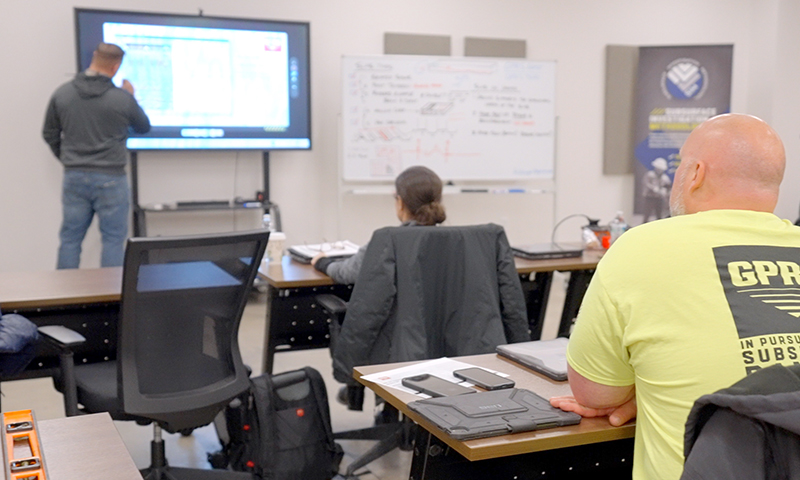

Back when Aston and his friends needed to be trained, the only place such training was available was from the company’s GPR supplier, GSSI. There was no industry standard for training certification for GPR in 2001, and although the American Society for Nondestructive Testing (ASNT) now provides some training standards, the minimum requirement for Level 1 certification remains a mere eight hours of classroom training. Once again, innovation was required to ensure that the growing team of professional Project Managers would all be held to the same, personally accountable, standards, no matter the job. Thus, Subsurface Investigation Methodology (SIM) was born.

SIM requires a minimum of 80 hours of classroom training and some 320 hours of mentored field training to achieve Level 1 certification. Similar requirements accompany the Level 2 and Level 3 SIM training. To make certain that every Project Manager achieves and maintains the rigorous SIMSpec requirements on the job, GPRS took SIM a step farther and built their own GPRS Training Academy, where PMs are trained in a setting unlike any other: More than 3,000 square feet of concrete slab filled with an increasingly complex maze of encased post tension cables, conduit, piping, rebar, USTs, and even an elevator shaft. Moreover, the company has partnered with The University of Toledo in a unique pilot program: GPRS PMs do mentored field work on the 150-year-old campus under the watchful eyes of their instructors, and the university receives complete visualization of its entire campus in return.

No GPRS Project Manager goes into the field solo until they have completed SIM Level 1 training. That means that they are expert in a wide variety of visualization and locating technologies, which could include GPR, 3D laser scanning, video pipe inspection (VPI), and more. Every GPRS Project Manager is empowered to consult with clients to look beyond what they have asked for to find what their job really needs. The unique combination of industry-leading training, the entrepreneurial spirit of GPRS Project Managers, and their fervent attention to detail is how GPRS has achieved and continues to maintain its 99.8% accuracy rate.

A satisfied GPRS customer, Sixtus Aliriagwu, Environmental Health & Safety Manager, DPR Construction, says, “With every project we do, we’re aiming for zero incidents, zero accidents, zero near misses, and zero unplanned interruptions to business operations… It’s very important to me, as a safety professional, to make sure we’re working safe every day, and doing the job perfectly without having any issues or incidents. GPRS plays a huge role in what we do.”

In fact, GPRS is so certain of the expertise of its PMs that it offers the Green Box Guarantee. When a GPRS Project Manager marks out a green box on a concrete scan with “clear” inside it and the customer cuts, cores, or drills into that spot and hits a line, rebar, or post tension cable, GPRS will pay the material cost to repair it. Period.

Only a company with complete confidence in its field team could provide such a promise.

So Much More Than GPR

Often, the most innovative ideas are the simplest. GPRS’ continual emphasis on accurate subsurface data collection and safety led to a natural evolution: the addition of more ways to “see” what’s underneath. Since 2007, the company has grown its service lines to include electromagnetic (EM) locating, leak detection, and NASSCO-certified video pipe (CCTV) inspection, among others, to expand customers’ knowledge of their subsurface infrastructure. Because accurate subsurface data is one of the most important components of a safe jobsite.

GPRS developed and exclusively sponsors two nationwide annual construction & infrastructure safety weeks: Concrete Sawing & Drilling Safety Week (CSDSW) in January and Water & Sewer Damage Awareness Week (WSDAW) in October. Further, they co-sponsor Construction Safety Week (CSW) each May. For each of these events, GPRS sends its safety experts onto jobsites, into trailers, and into board rooms to educate workers, safety professionals, and stakeholders on the importance of following best practices when cutting or coring concrete, how to stay safe on the jobsite, and how to prevent cross bores, non-revenue water loss, and accidents caused by utilizing trenchless technology without accurate subsurface information.

Once the company was certain it could find and provide pinpoint-accurate data for everything underground, it became apparent that they were limiting themselves (and their customers) to subsurface technologies. So, GPRS innovated again. This time, one might say it was the tip of the iceberg of the biggest innovation GPRS has undertaken.

In 2022, GPRS acquired TruePoint 3D Laser Scanning, and added 3D laser, Matterport, and drone photogrammetry to its subsurface service lines. 3D laser’s LiDAR technology allows for millimeter-accurate 3D measurement of even the most dangerous and difficult-to-reach places, and Project Managers can utilize Matterport and 3D laser scanners to capture their utility locating, VPI, leak, and concrete markings to build a complete, integrated data set that allows customers to see accurate as-builts of an entire site, above and below ground. To our knowledge, GPRS is the only company in the United States able to offer complete site visualization services on a national level.

Just as the company has adopted an industry-leading standard with SIM, GPRS Project Managers who specialize in 3D laser scanning are required to complete an additional 40 hours of classroom and mentored application training before utilizing the technology for our customers.

This is why they say GPRS Intelligently Visualizes The Built World.™

What Does GPRS Do With All That Data?

It is difficult to imagine the sheer volume of subsurface, utility, telecommunication, construction, concrete, 3D laser, sanitary and storm sewer, and water infrastructure data GPRS has built up in over 22 years of business and almost half a million jobs.

One of the many lessons learned along the way is that it’s difficult to visualize the data for a single utility locate, let alone the complexity of information that comes from a full above and below ground site scan. So, the company set out to make visualizing their subsurface and above ground data as easy as possible.

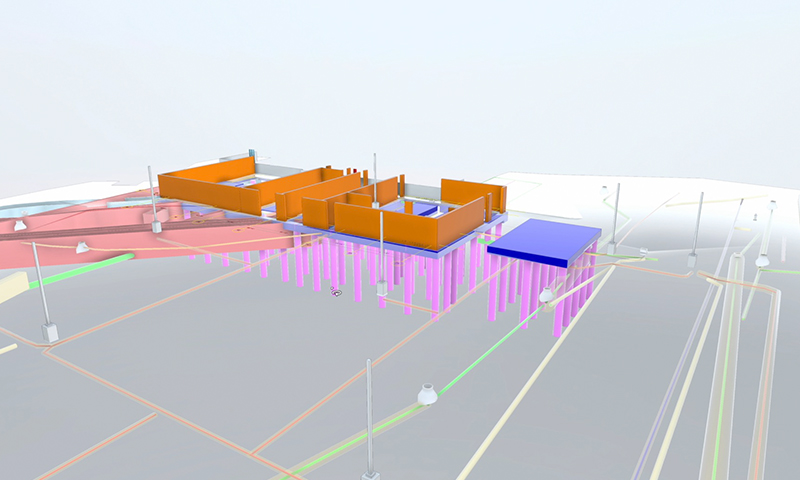

In 2019, GPRS created a dedicated in-house Mapping & Modeling Team to do just that. This group of CAD experts and 3D designers can take anything from a simple GPS-mapped utility locate to a full site scan and create the drawings, maps, and 3D BIM models – the accurate, updated as-builts clients need – to design, plan, prefabricate, build, renovate, and maintain their buildings, facilities, and campuses, above and below ground.

And, because the “boots on the ground” collecting that data are experts in safety and accuracy, the Mapping & Modeling Team can create some astonishing results: like an integrated 3D BIM model that married the architectural and engineering data to the GPRS-collected as-built information to show a comprehensive above and below ground picture of a proposed healthcare center expansion, CAD drawings and 3D models of draped post tension cables in a new Detroit high-rise to aid design and construction planning, and a complete facility subsurface and aboveground walk-through for a Big Three automotive plant.

In short, if you need to see it, GPRS can visualize it for you.

In the first example mentioned above, the integrated 3D BIM model GPRS created showed that the proposed building footprint had been mis-measured by three full feet. A video pipe inspection found that there were previously undetected brick sanitary sewers, possibly dating to the 1850s, running under the proposed construction site. Project Managers also located a large concrete slab that had been covered by soil and asphalt, which would impede the installation of several of the 100 concrete caissons the client intended to install 65 feet below the surface for structural support.

All of those findings, and millimeter-accurate 3D laser scanning data, were represented in the detailed digital model, allowing every part of the massive project team to see what they were dealing with and adjust their plans before breaking ground.

Over nearly half a million jobs, many with national scope, GPRS has discovered unknown underground storage tanks (USTs), abandoned water and sewer lines, voids, and has provided updated, accurate subsurface and concrete infrastructure data that has saved clients millions of dollars, thousands of man hours, and most importantly, allowed their customers’ crews to get home safely every night.

The Future: Data Control = Damage Control

GPRS created the industry standard for digital data delivery in 2020 with its Job Services Report & Submittal Letter, where customers can view, download, copy, and share their accurate infrastructure as-builts among their team. Even though that delivery method was revolutionary, it still created information bottlenecks, data fragmentation, and led to miscommunications and costly mistakes. Mistakes everyone wanted to avoid.

So, Aston and his team envisioned and developed a solution: SiteMap®, powered by GPRS.

SiteMap® is the culmination of everything GPRS has spent more than two decades learning about construction, site safety, design, and engineering, distilled into an intuitive user interface that houses the accurate infrastructure data GPRS collects for its customers – mapped, layered, and cross-referenced, so it can be controlled and securely shared to break down information siloes, eliminate communication bottlenecks, and redefine collaboration for organizations in every area of the construction industry.

Currently, SiteMap® houses layered subsurface utility data for individual jobs, projects, facilities & campuses, and distributed national portfolios. Every outdoor utility locate job GPRS completes now also comes with a complimentary SiteMap® Personal subscription. GPRS provides customized subscription tiers for full project, facility, or portfolio visualization via SiteMap® Project, Pro, and Team.

So Much More Than GIS

Unlike the GIS platforms the industry has come to expect, SiteMap® houses 99.8% accurate data because GPRS collects, refines, and visualizes it. The goal is to eliminate miscommunication and data fragmentation to keep projects on time, on budget, and safe.

As SiteMap’s applications expand, subscribers will soon be able to access their CAD drawings, BIM models, conceptual site models, VPI reports, and even 360-degree construction progress updates and records via TRUBuilt, FLRPLN, and WALKTHRU 3D.

So, when a SiteMap® subscriber needs to share as-built infrastructure data with subcontractors, architects and engineers, surveyors, or stakeholders, they can curate the user experience to put only the data their team needs into their hands exactly when they need it. The SiteMap® app makes it possible to access job, project, and aggregated historical facility data from any laptop or mobile device, 24/7.

The construction world has been slower than most industries to accept and utilize digitized data. That lag time has led to incomplete and inaccurate as-builts, utility strikes, accidents, reworks, change orders, and even building collapses – events that all could have been greatly reduced or avoided by capturing and maintaining accurate as-built data.

GPRS’ goal is to provide the accurate data its customers need to keep their projects, their budgets, and their workers safe. That was Matt Aston’s mission 22 years ago, and it remains the core of GPRS’ mission – continual innovation in pursuit of 100% subsurface damage prevention.

For More Info: https://www.gp-radar.com/

About the Author

Jason Schaff

Senior Vice President of Marketing and SiteMap® Product Executive at GPRS

Schaff has taken many personality profile type tests over the years. While none of them tell the complete story, they communicate who he is as a leader, innovator, and builder. Whether it is the StrengthsFinder results of individualization, strategic, futuristic, command or competition, the DISC assessment results of being a high Ds, a Predictive Index result of being a “Maverick,” or being defined as an Enneagram type 8, each informs on Jason’s strengths and what it is like to work or interact with him in a business setting.

He is often described as an innovative, outside-the-box thinker who is undaunted by failure, and that is borne out in the trajectory of his career. Schaff loves the challenge of building new things. His evolution at GPRS over the last 14 years places him in building mode, time and again. Whether starting a new office, program, team, department, or initiative, he is grateful to have the opportunity to be a “starter” for GPRS. He loves being the creative or visionary leader on a team.

His love of leadership has nothing to do with being “the boss.” In fact, he states, “My favorite thing about leadership is being able to take a front row seat in watching team members go from new hire to finding their purpose. Whether it is a raise, promotion, departmental transfer or even exiting the organization for a better opportunity, it is truly the best part about leading and the roles that I get to play.”